HPU and Hydraulic systems

Your partner for hydraulic solutions since 2007

DVG specializes in emergency valve control through actuators, as well as in the design and manufacture of pneumatic and hydraulic power and control systems.

In particular, we design and produce highly customized hydraulic power units (HPU), developed to meet complex technical requirements and critical applications.

DVG Automation operates in compliance with the legal requirements set out by the applicable European Directives, including regulations on explosion protection (ATEX), the Machinery Directive, the Cableway Installations Directive, and the Pressure Equipment Directive.

ANNUAL PRODUCTION CAPACITY:

More than 250 Hydraulic Power Units (HPUs) sold in 2025

We engineer performance

HPU in action: current applications

OIL & GAS

HPU to control actuators and valves on offshore platforms and pipelines.

PETROCHEMICAL PROCESS CONTROL

Electro-hydraulic solutions for a precise control of process valves.

MARINE APPLICATION

HPU designed to withstand corrosion.

ENERGY SECTOR USAGE

Robust HPU for turbines blades orientation.

HPU components

CONTROL PANELS & CABINETS

Open or watertight cabinets for electro hydraulic regulation and control components.

Key Features:

- All stainless-steel construction.

- Custom designs based on application.

- Cabinets rated up to IP67, with transparent door.

- Front-side component assembly.

- Direct (flanged) mounting to controlled device.

- Single-component maintainability (no need to disassemble others).

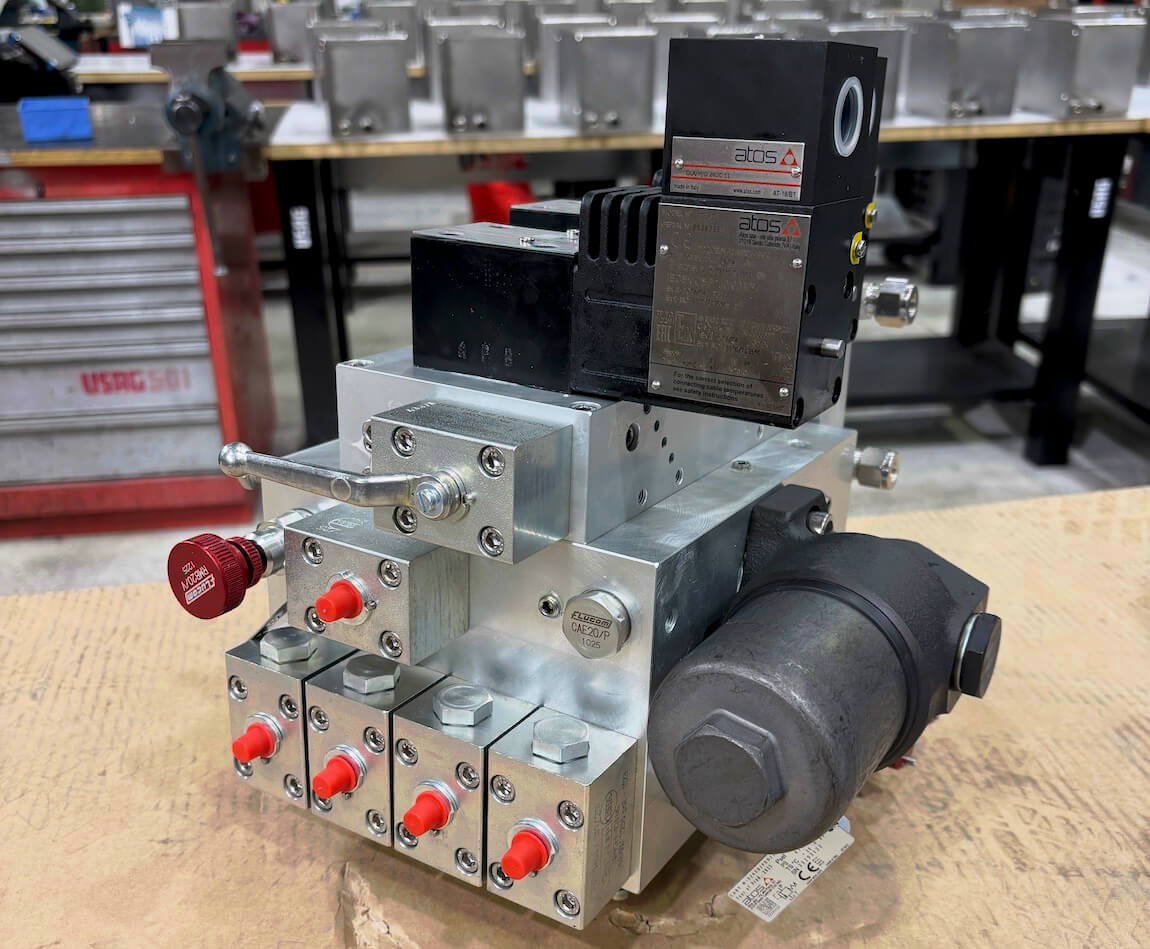

HYDRAULIC BLOCKS

High-quality solutions for complex circuits with compact layouts.

Key Features:

- Solenoid valves

- Proportional valves

- Servo valves

- Logic elements

- Cartridge valves

High-Quality, Explosion-Proof Hydraulic Systems

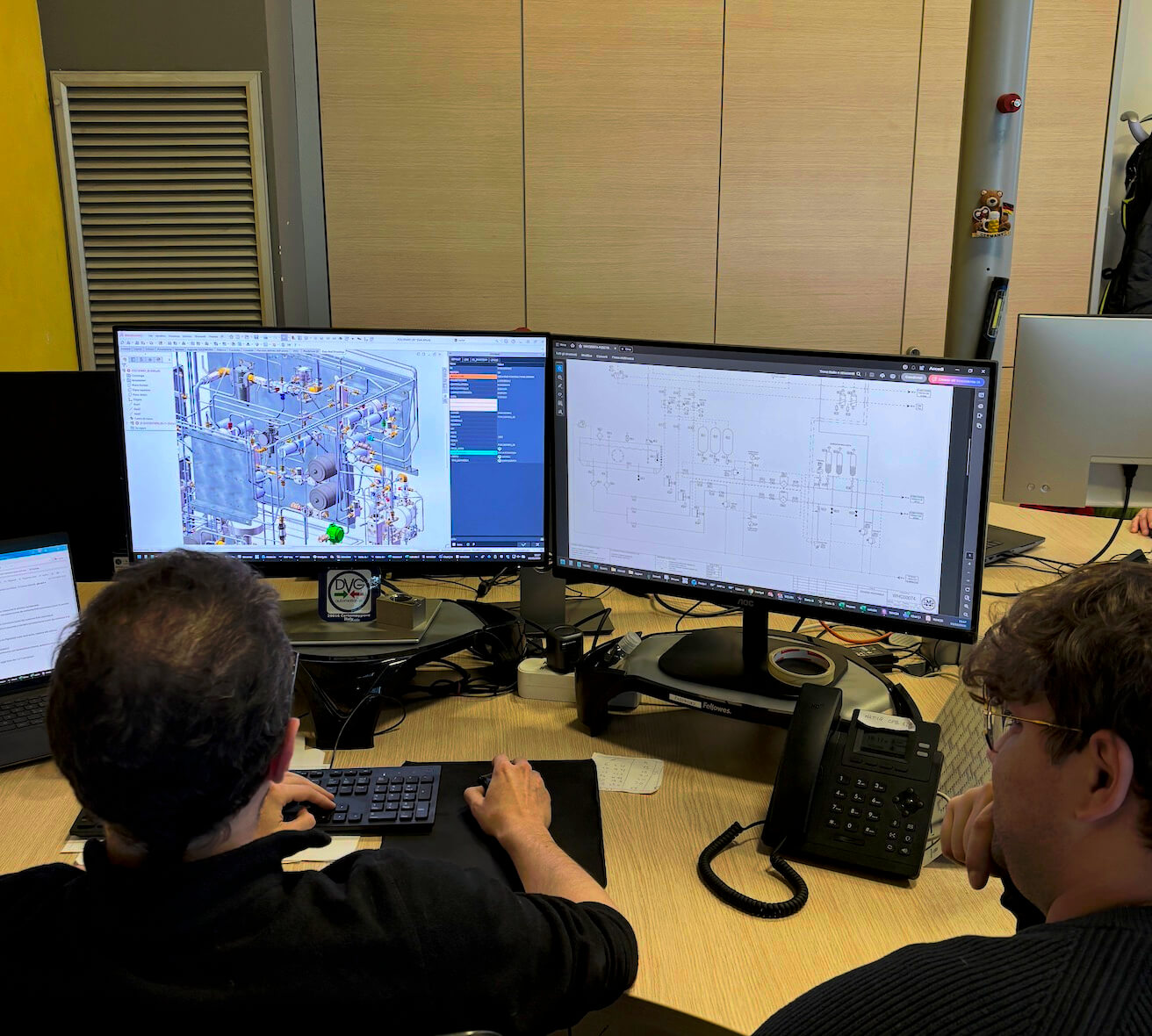

100% In-House Production with CAD/CAM technology.

Explosion-Proof Options (ATEX 2014/34/EU, IEC, NEC – ex-d/e/m/i).

Emergency Hand Pump and Oil Reservoir with accessories.

Closed Cabinet option and ASME–PED Accumulator.

Monitoring: Oil level, temperature, and hydraulic pressure.

Local Control: Indication lamps and electric control.

Optimized Design: Block-mounted controls to reduce tubing and leakage.

Technical specifications

Pressure: up to 690 bar (10,000 psi)

Temperature: -60°C to +85°C

Power Supply:

• AC: 115/230 V 1Ph – 380…480 V 3Ph – 50/60 Hz

• DC: 24/110 V (ESD: 24/48/110 V DC)

Electrical Power: up to 250 kW

Flow Rate: 50 cc/min – up to 1,000 L/min

Materials: AISI 316/316L, Carbon Steel, Aluminum, 6Mo, Inconel625

Safety: SIL2 (up to SIL3 with 1oo2 SOVs)

Certifications: ATEX, IECEx, UL/FM, PED, IEC 61508, Machinery Directive

Documentation: 2D/3D drawings, test certificates, component datasheets

Customization: Fully tailored to end-user specifications

Write to us

DVG Automation Spa

SALES

Write to us sales@dvgautomation.it

AFTERSALES

Write to us aftersales@dvgautomation.it